What We Packed for PACK EXPO Chicago

The next PACK EXPO International show is in Chicago and is just a couple of weeks away, but we are so excited about what we are exhibiting at the show that we had to share it! So whether you are exhibiting or just attending, don’t miss the opportunity to stop by our booth! If you visit our booth #4020, you will see the most versatile machinery at the show! Some of our machinery you can not purchase anywhere else, and all of our machinery can print on different substrates for various industries.

Our Packed Machinery:

VFS-1000: Vertical Feeding System

This year we are bringing THREE VFS-1000s! The VFS-1000 Vertical Feeding System was designed for zippered pouch feeding and bag feeding that have long been an issue to run on traditional methods. The system allows for pouch labeling. Stand-up pouches and bags are stood on the edge, picked and placed onto a shuttle table, then pushed onto the downstream conveyor for printing or pouch labeling. The System can run up to 60 pouches or bags per minute, depending on the size of the pouches and bags. Pouches and bags are aligned as they are pushed onto the receiving conveyor.

The VFS-1000 will be attached to the equipment listed below, showcasing its unique versatility!

SPD-1175: Single Pass Digital Printer

The SPD-1175 will be coupled with one of our VFS-1000 feeding systems. This overprinting system is one of HSAUSA’s newest specialty color printers. It is based on the HP FI-1000 technology and utilizes HP Page Wide full-color thermal inkjet technology to deliver durable, pigment-based ink at high speeds, all at the industry’s lowest variable cost. This single-pass digital printer can print short-run, full-bleed, variable data jobs, but the HP FI-1000 printhead also prints wider (up to 11.7”) and on thicker substrates with an adjustable printhead height of up to 2.” This allows for printing on an endless variety of media sizes and types.

ALRITMA X High-Speed Label Applicator

The ALRITMA X is a high-speed self-adhesive label applicator that is distributed by Dartronics, Inc. It will be attached to one of the VFS-1000s showcasing its extraordinary capacity, endurance, precision, and speed. It is fitted with an HP (high-performance) kit composed of a silicone-paper motorized rewinder unit as well as an innovative “push-pull” label web-drive system. It has high positioning accuracy even with variations of the product transit speed. The ALRITMA X is well adapted to large workloads, such as on rotary labelers, particularly in applications using printers/markers with their checking devices.

The TIPC15 (Touch Controller Premium) will be attached to the third VFS-1000. The TIPC15 is a premium touch controller that is delivered with the Windows 10 operating system and OBJ InkDraw printing software. OBJ InkDraw is our software that is specially designed for coding/marking applications. With a crypto-key, features of the Mail InkDraw are also available. The Touch Controller’s remote control has a comprehensive communication protocol allowing you to remotely control the unit. Remote management is done through Ethernet or serial connection. And its industrial casing is a black anodized aluminum frame and steel case that provides extra protection for harsh industrial environments.

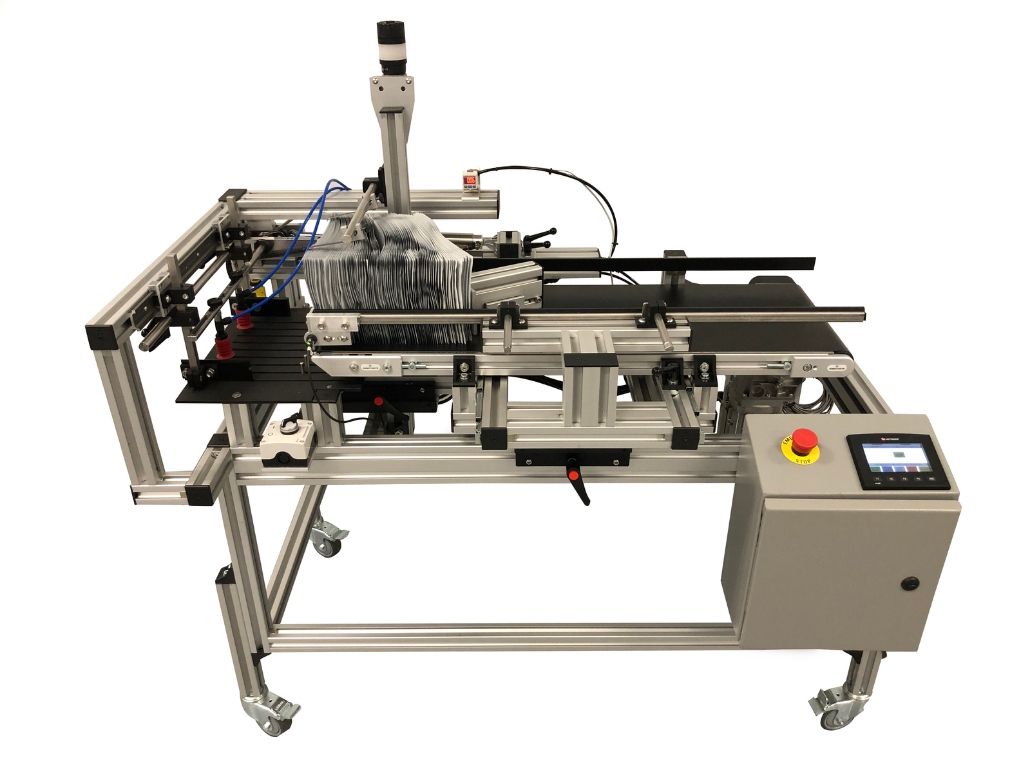

VCT-3000: Vertical Case Transport

Our custom-built vertical case transport is one of our most popular systems. It is designed to run flat cases before they are erected and filled. The system can be integrated with inkjet printers or labelers for marking up to all four sides in a single pass. We integrated it with the DJ-240, MiniTouch, and printheads. The system requires no plant air. The system comes with a belt feeding system on the in-feed, a hugger belt system for the drive, and a stepper-driven re-stacker. Designed to run 24/7 with minimal maintenance. The system is built out of stainless steel and aluminum. The PLC allows for many features. All speeds are independently adjustable and saved by recipes. It gets the job done fast, with speeds of up to 200 feet per minute!

The equipment below will be attached to the VCT-3000:

DJ240 Industrial InkJet Printer

The DJ240 system can control up to 4 print heads for a total print of 280mm. Each print head prints 70mm (2.8″). Every print head has its own ink delivery system. Advanced ink delivery system with auto-prime and drain ink from the system with no mess Its controller allows for simple message creation and editing. The software allows connectivity to a database, create your template and link them to the database allowing thousand of sku’s.

Finally, we are bringing one of our most requested products to PACK EXPO Chicago: the MiniTouch. It is always a customer favorite because it is easy to integrate and use. With its small size, the controller fits where you want it. With the printheads mounted externally, the printer can be used for down print as well as side print. The compact version (MiniTouch and side/low printhead) gives you a controller and printhead in one unit, making it ideal for side printing, e.g. on boxes.

The HSAJET® MiniTouch MTHP4 can control up to 2″ print height. Mount the controller directly on a one or two pen printhead (side/low version) for a compact version, or utilize the flexibility of the MiniTouch to connect up to 4 pens to the controller, either as single heads or with a distributor box in a combination of 1, 2, and 3-pen printheads.

Everything we show at PACK EXPO Chicago will be available for purchase at our booth #4020. It’s not too late to sign up to attend the show for free: using our comp code: 25T73.