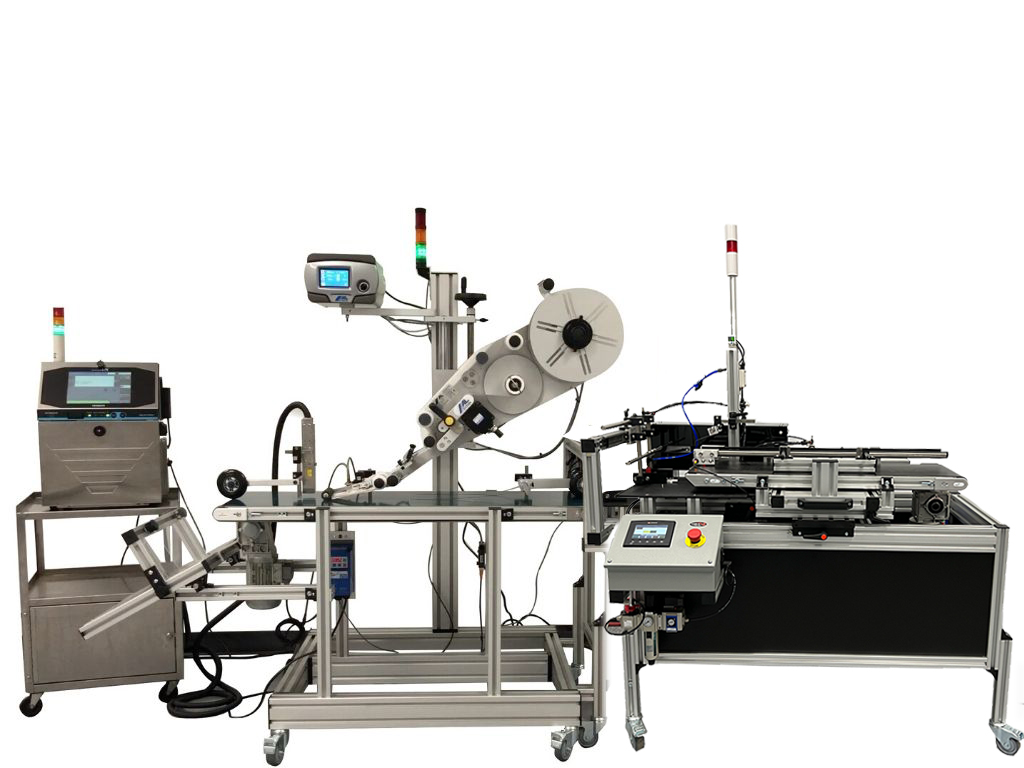

The VFS-1000 system was designed for zippered pouch feeding and bag feeding that have long been an issue to run on traditional methods. The system allows for pouch labeling.

Stand-up pouches and bags are stood on edge, pick and placed onto a shuttle table, then pushed on to the downstream conveyor for printing or pouch labeling.

The System can run up to 60 pouches or bags per minute depending on size of pouches and bags.

Pouches and bags are aligned as they are pushed onto the receiving conveyor.

See the HFS-2000, Horizontal Feeding System for ink jet printing onto cartons. Great for GS1 barcodes and UDI applications.