Best Barcode and Vision Inspection Systems

At HSAUSA, we offer our customers the best barcode and vision inspection systems to fit their needs. We understand barcode reading capabilities are necessary to ensure traceability, quality, improved efficiencies, and accurate inventory management in a wide variety of industries. Our products combine high-performance tools and intelligent features that are capable of solving thousands of applications from item detection, part positioning, flaw analysis, measurement, and quality assurance from simple verification to complex inspections.

Our Barcode and Vision Inspection Products

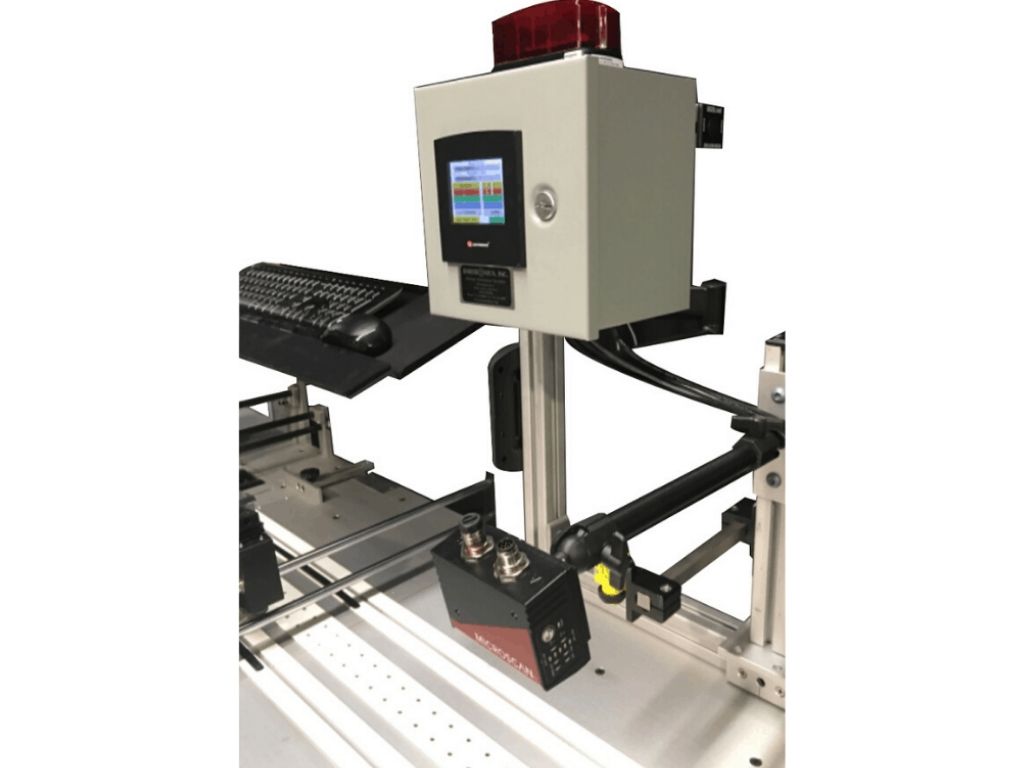

BSC-350 Barcode Scanner Controller

The BSC-350 Bar Code Scanner Controller controls up to two barcode scanners or barcode verifiers. The touchscreen interface has simple-to-use operator functionality. Alarm Light audible buzzer and alarm output to external devices plug‐in connector. Provides 100% inspection of 1D or 2D Barcodes (dependent on the type of scanner or imager connected.

Teach the controller with a handheld scanner, and the scanned codes will be confirmed against the taught code. If any NO READ conditions occur, the system can be set up to track and reject the printed or labeled case.

The color display indicates the quantity of read codes, the taught code, NO READS, MISMATCH, and GOOD READS, with independent adjustments to set the thresholds. The system will alert the operator via an alarm light and buzzer. If the thresholds are met, the system will stop upstream devices in order to correct the error.

Optional reject mechanisms can be added to the system to ensure the cases have been rejected. The reject sensor verifies this condition.

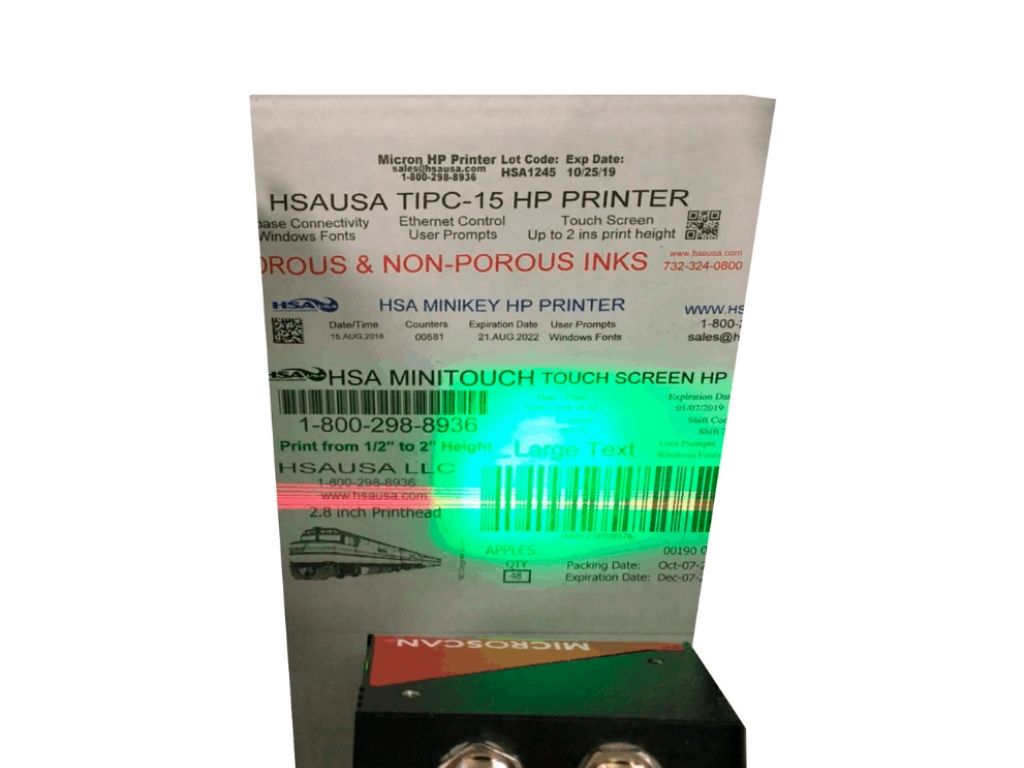

BSC-550 Barcode Scanner Controller

The BSC-550 Bar Code Scanner Controller controls up to two bar code scanners or verifiers. Provides Touch Screen interface with simple-to-use operator functionality. Alarm Light audible buzzer and alarm output to external devices plug‐in connector. Provides 100% inspection of 1D or 2D Barcodes (dependent on the type of scanner or imager connected.

Teach the controller with a handheld scanner, and the scanned codes will be confirmed against the taught code. If any NO READ conditions occur, the system can be set up to track and reject the printed/labeled case.

The color display indicates the quantity of read codes, the taught code, NO READS, MISMATCH, and GOOD READS, with independent adjustments to set the thresholds. The system will alert the operator via an alarm light and buzzer. If the thresholds are met, the system will stop upstream devices in order to correct the error.

Optional reject mechanisms can be added to the system to ensure the cases have been rejected. The reject sensor verifies this condition.

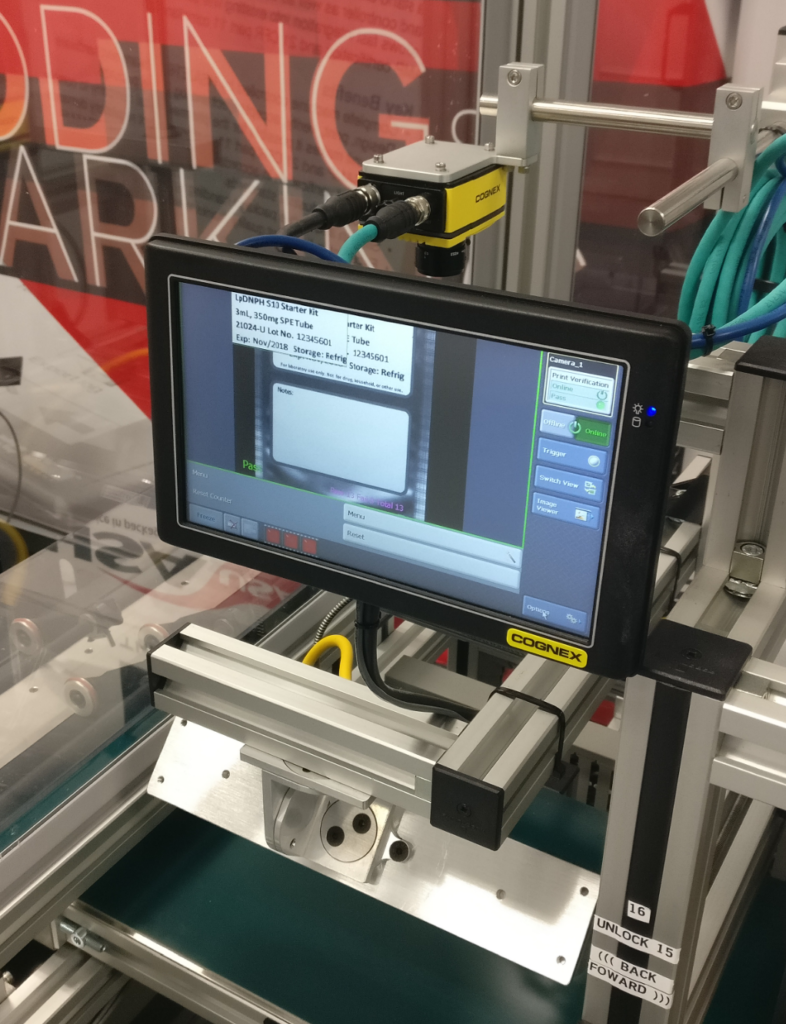

Cognex In-Sight® Track & Trace

The complete identification and data verification solution for healthcare serialization. In-Sight® Track & Trace works with your networked In-Sight vision system to create a complete identification and data verification solution for Digital InkJet printed on pharmaceutical and medical device packaging.

- Reads 2-D and 1-D barcodes: Data Matrix, GS1-128, GS1 DataBar, securPharm and Pharmacode

- Verifies correct ID code contents, including compliance with the GS1 Healthcare data standard

- Conforms to 21 CFR Part 830 GS1 validation for Unique Device Identification

- Supports FDA 21 CFR Part 11 validation compliance with change tracking, double-blind and secondary authentication

- Provides Data Matrix Mark Quality Assessment during production to detect changes in print quality

- Verifies the accuracy of printed text

- Detects InkJet misalignment and skew

- Supports bundle aggregation

Conforms to 21 CFR Part 830 GS1 Validation for UDI: Track & Trace validates plain text to GS1 linear and Data Matrix codes meeting the FDA’s Unique Device Identification label requirements for 21 CFR Part 830. With Cognex Track & Trace validation documentation, In-Sight Track & Trace easily integrates into any serialization packaging line.