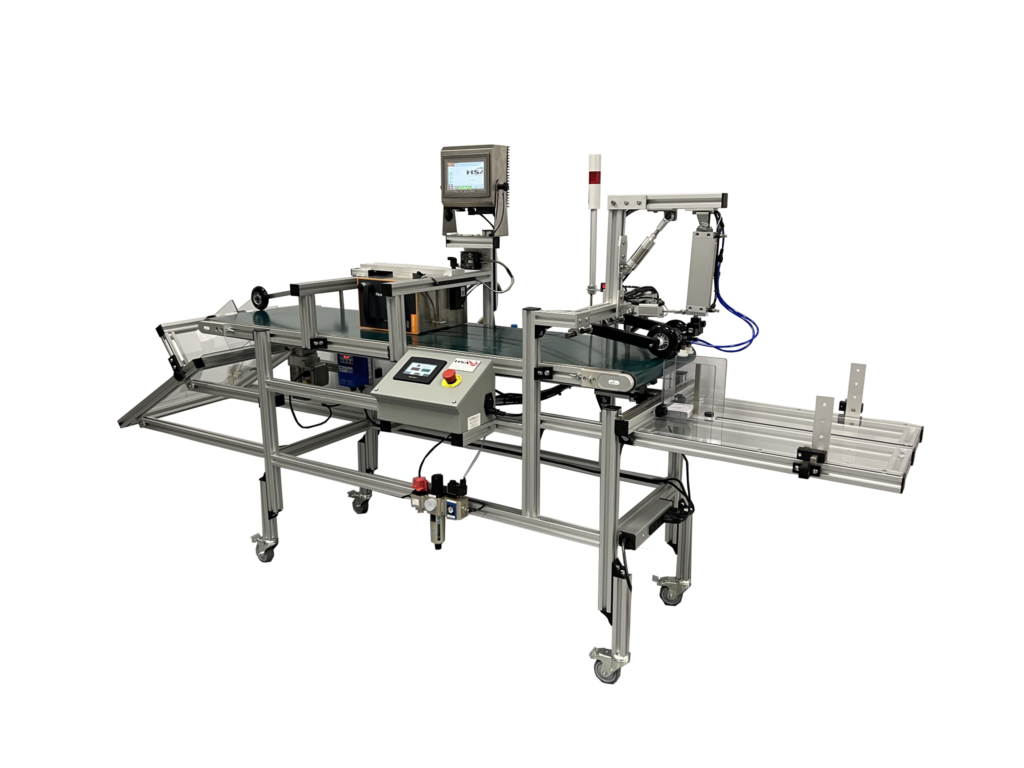

New System for Picking & Placing Flat Lying Pouches/Bags!

The HFS-2506M is our new stand-alone horizontal feeding machine built to pick and place flat-lying pouches/ zippered bags. This custom solution was created for a customer who needed a standalone system to feed and directly print onto various sized pre-made pouches. Our 300 dpi print heads on self-leveling mounts provide superior code quality through every run!

We intergrated our HFS-2000 horizontal feeding system with a FlexPackPRO® 420 Series TTO (Thermal Transfer Overprinter).

FlexPackPRO® 420 SERIES Model: FPP 420cXTL

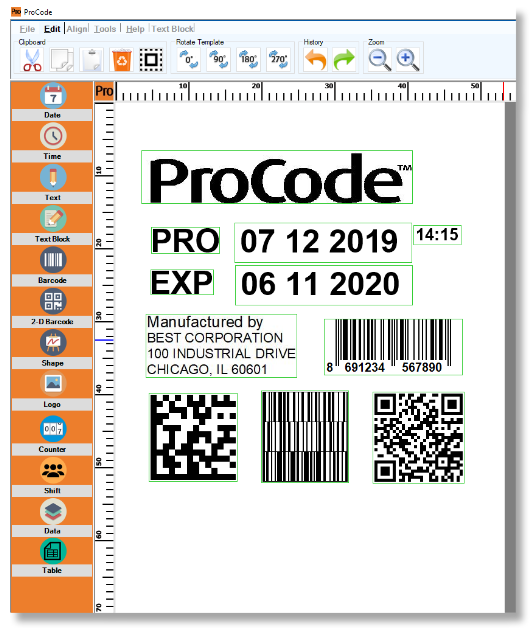

The “FlexPackPRO® 420cXTL Thermal Transfer Overprinter was integrated with the HFS-2506M. The FPP 420cXTL thermal transfer overpritner comes with full-featured coding design software, ProCode™ Professional.

FPP 420cxTL Features:

- 107mm (4.2”) wide, 300dpi Printhead

- Print larger combinations of codes, logos, text and graphics

- Continuous & Intermittent models

- Excellent option for printing variable ingredients and nutrition panels

- Up to 4.2” x 10” print area

ProCode™ Professional Features

- Full linear and 2-dimensional barcode

- WYSIWYG interface with previews

- Full downloadable font support

- Fixed, variable and merged text fields

- Multiple graphic formats supported

- Shift coding and real-time clocks

- Automatic “best before” date calc.

- 5,000+ unique image file memory

- Incrementing/decrementing text, counters & codes

SEE THE HFS-2506M SYSTEM IN ACTION!

HFS-2506M FEATURES:

- Labeling/TTO can be added ontop of supplied conveyor

- Up to 50 Pouches/Zippered bags per minute*

- Adjustable in-feed hopper

- PLC Controlled

- Recipes for different product setup

- Integrated with FPP 420C TTO Printer

- Catch bin

- Variable speed adjustment

PLC Contoller:

- PLC controlled, touch screen interface

- Painted Steel Cabinet

- Voltage: 120 VAC, 4 amps, 60 Hz

- Alarm output connections (2 Amp rating)

- Emergency Stop

- Up to 30 stored recipes

- Adjustable timers

Catch Bin:

- Adjustable guides to handle product 15” wide x 15-1/2” long – Standard Machine

- Modification to standard machine to run pouch sizes as indicated on Page 4

- Wheel drives product out into the hopper.

In-Feed Hopper

- 4” or 6” deep infeed hopper**

- Adjustable guides

- Product up to 15” wide x 15-1/2” long – Standard Machine

- Modification to standard machine to run pouch sizes as indicated on Page 4

- Dual adjustable suction cups for proper picking

For more info on the HFS-2506M horizontal feeding system, call 732-324-0800 or email: sales@hsausa.com